NFPA 70B compliance is now a real requirement that businesses can no longer ignore.

Electrical failures remain one of the leading causes of commercial fires and unplanned downtime. This guide explains what businesses must do, what most online resources miss, and how to apply the rules in a practical way that actually protects people and equipment.

| According to FEMA and safety industry data, there were over 8,000 non-residential electrical fires in 2022, resulting in more than $374 million in losses. Businesses without proper electrical maintenance are at higher risk of these failures. |

What Is NFPA 70B and Why Businesses Must Pay Attention

NFPA 70B is the standard for electrical equipment maintenance published by the National Fire Protection Association. It sets clear expectations for how electrical systems should be inspected, tested, maintained, and documented over time.

For years, many businesses treated it as optional guidance. That changed when it became a formal standard. Today, insurance providers, safety auditors, and authorities having jurisdiction increasingly expect organizations to follow it as part of a responsible maintenance program.

The goal is simple. Reduce electrical failures, lower fire risk, prevent injuries, and improve system reliability.

What NFPA 70B Actually Requires From Businesses

This is where many competitors stay vague. The standard is not just about doing inspections. It requires a structured and documented system.

- A documented electrical maintenance program

Every facility must have a written program that explains how electrical equipment is maintained. This includes who is responsible, what tasks are performed, how often they occur, and how results are recorded.

- Condition-based maintenance

Maintenance intervals are not random. Equipment must be evaluated based on condition, usage, environment, and criticality. A dusty manufacturing plant and a climate-controlled office cannot follow the same schedule.

- Inspections, testing, and corrective actions

Visual inspections alone are not enough. Testing methods such as infrared scans, torque checks, and functional testing are expected where appropriate. Any issues found must be corrected, not ignored.

- Records that prove compliance

If it is not documented, it does not count. Records must show inspections, test results, repairs, and follow-up actions.

Electrical Equipment Covered Under NFPA 70B

Most businesses do not realize how broad the coverage is. The standard applies to nearly all electrical distribution equipment.

| Equipment Type | Maintenance Focus | Why It Matters |

| Switchgear | Inspection, cleaning, thermal scanning | Prevent arc flash and outages |

| Circuit breakers | Functional testing and lubrication | Ensure proper fault clearing |

| Panels and MCCs | Tightening connections and labeling | Reduce overheating risks |

| Transformers | Thermal inspection and condition checks | Prevent insulation failure |

| Grounding systems | Continuity and integrity testing | Reduce shock hazards |

Ignoring any of these increases the chance of failure at the worst possible time.

Step-by-Step Guide to NFPA 70B Compliance

This is the practical part most blogs fail to explain clearly.

Step 1: Perform an electrical system assessment

Start by reviewing existing equipment, maintenance history, and documentation. Many facilities discover outdated drawings or missing records at this stage.

Step 2: Update documentation

Single line diagrams, equipment lists, and maintenance logs must reflect current conditions. Outdated records create safety risks and audit problems.

Step 3: Identify hazards and deficiencies

Loose connections, signs of overheating, damaged insulation, and obsolete equipment should be documented and prioritized.

Step 4: Define maintenance tasks and intervals

Use equipment condition and environment to set realistic schedules. Critical systems often require more frequent attention.

Step 5: Perform inspections and testing

Qualified personnel carry out the required work using approved procedures and tools.

Step 6: Correct problems found

Deferred repairs are one of the most common compliance failures. Issues must be addressed and verified.

Step 7: Train and verify qualified personnel

Only properly trained individuals should perform electrical maintenance. This protects both workers and the business.

Step 8: Audit and improve the program

Regular reviews help ensure the program stays effective as equipment and operations change.

Who Is Considered Qualified Under NFPA 70B

This is a major gap in competitor content.

A qualified person is not just someone with experience. They must understand the equipment, recognize hazards, follow safe work practices, and use proper testing methods. Many businesses choose licensed electrical contractors for this reason, especially for high-risk systems.

Documentation That Auditors and Insurers Expect

Proper documentation often determines whether a facility passes or fails a review.

You should maintain:

- Inspection and test reports

- Maintenance schedules

- Records of corrective actions

- Training documentation

- Equipment identification and labeling

Digital systems help, but consistency matters more than format.

How NFPA 70B Connects With Electrical Safety Rules

Maintenance work still involves risk. Safety practices such as lockout procedures, arc flash protection, and job planning must align with workplace electrical safety requirements. Maintenance and safety programs should support each other, not operate separately.

Common Compliance Mistakes Businesses Make

Many facilities struggle because they:

- Rely only on manufacturer manuals

- Skip follow-up repairs

- Use untrained staff for testing

- Lacks consistent documentation

- Treat maintenance as reactive instead of planned

These mistakes increase liability and risk.

Get Professional Help for Electrical Maintenance and Compliance

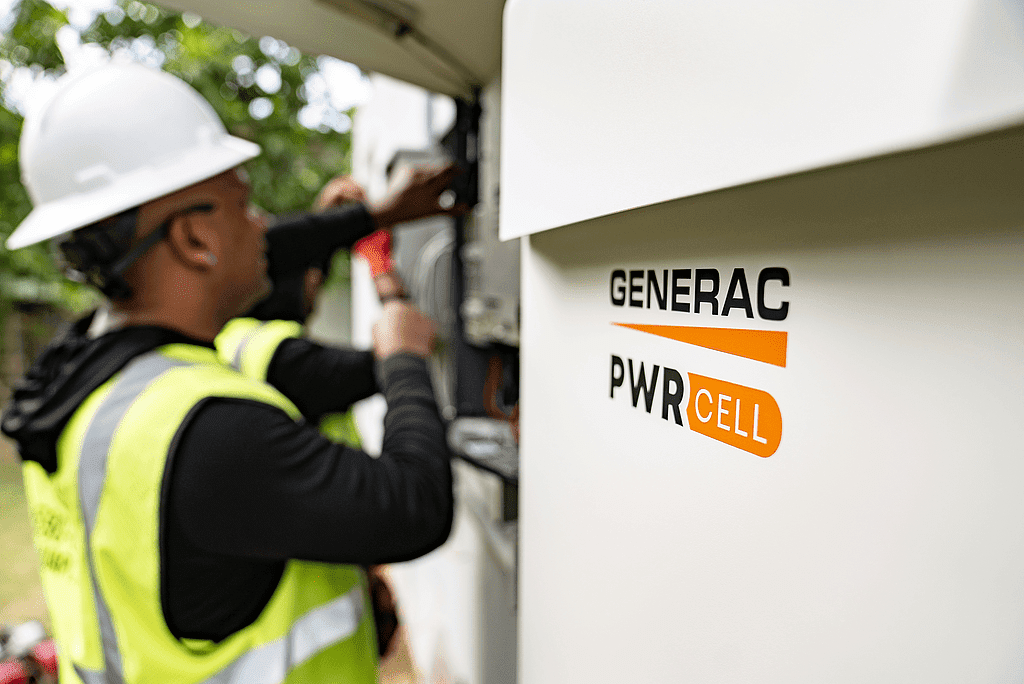

Electrical maintenance and compliance can be complex without the right support. Catale Company Electric provides expert inspections, testing, and preventive maintenance to help businesses reduce risk and meet NFPA 70B requirements.

Reach out to Catale Company Electric to discuss your electrical service needs.

Frequently Asked Questions (FAQs)

How long does it take a business to become compliant with NFPA 70B?

Most businesses can reach NFPA 70B compliance within a few months, depending on system size, existing documentation, and how quickly inspections and corrective work are completed.

Does NFPA 70B apply to small commercial buildings and offices?

Yes, NFPA 70B applies to small commercial buildings, offices, and retail spaces that have electrical distribution equipment requiring inspection, maintenance, and documentation.

Are infrared inspections required for NFPA 70B compliance?

Infrared inspections are strongly recommended under NFPA 70B because they help detect overheating connections and hidden electrical issues before failures occur.

Can poor electrical maintenance affect insurance coverage or claims?

Yes, insurance providers may delay, reduce, or deny claims if electrical failures occur and proper maintenance records required by NFPA 70B are missing.

How often should an electrical maintenance program be reviewed or updated?

Electrical maintenance programs should be reviewed regularly and updated whenever equipment is replaced, loads increase, or inspections reveal new risks